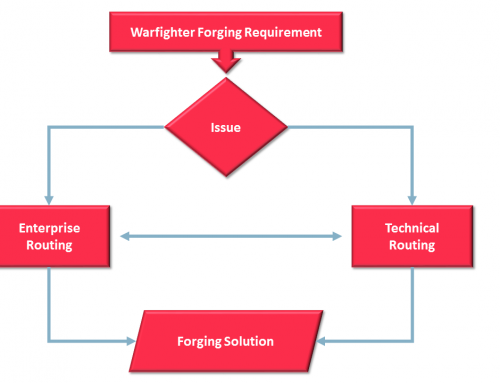

Respondent Area of Interest

Ensuring part-to-part consistency and process integrity is crucial for the supply chain, as well as end-user performance. Developing new knowledge to replace longstanding skill and knowledge loss is also a factor. Considering the rapid advances in sensor application and data analytics, the forging supply chain stands to benefit tremendously.

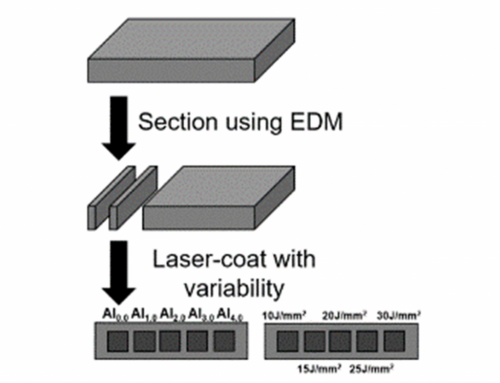

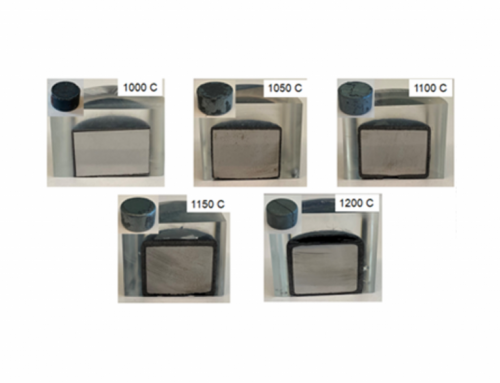

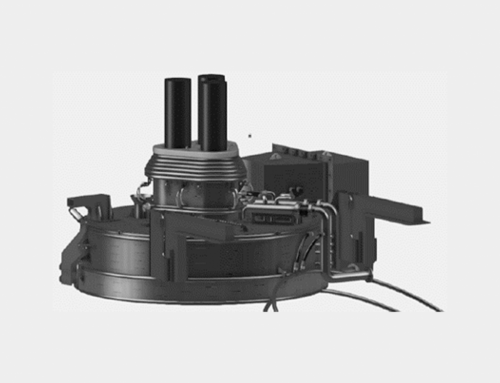

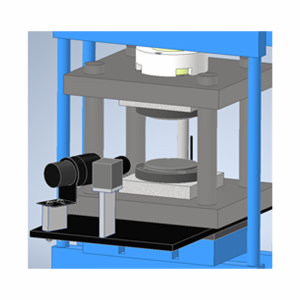

Project: Intelligent Monitoring of the Impression Die Forging Process – IFT program

Objective:

Develop the groundwork for machine-learning algorithms that would be used to develop the control logic needed to automate and develop smart forging processes.

Solution:

Demonstrating multiple sensor analysis with the ability to be processed by a control system will establish the groundwork for developing machine-learning algorithms, which will improve part lead times, reduce defects, and ensure a consistent supply base.

Principal Investigators: